| View previous topic :: View next topic |

| Author |

Message |

diegowhite

Faceplant

Joined: 23 Oct 2008

Posts: 36

City: Dublin

|

Posted: Feb 12, 2009 7:13 am Post subject: Posted: Feb 12, 2009 7:13 am Post subject: |

|

|

Got the new 9HP engine yesterday, it's a BEAST, and twice the size of the 6.5HP.

In order to get the TAV on now we're going to have to grind down some of it and also grind some down of the engine base. Are there negatives to this like making the base suseptible to cracking?

You can see where need to cut in the green

|

| Description: |

|

| Filesize: |

54.83 KB |

| Viewed: |

9662 Time(s) |

|

|

| Back to top |

|

|

|

|

JeffKnox

Backside 180

Joined: 09 Apr 2007

Posts: 2044

City: Jacksonville/Gainesville

|

Posted: Feb 12, 2009 9:36 am Post subject: Posted: Feb 12, 2009 9:36 am Post subject: |

|

|

grind away.... i grinded the shizzle out of both of mine

_________________

PAVT since '05/'06 |

|

| Back to top |

|

|

Montgomery

Backside 180

Joined: 26 Feb 2008

Posts: 976

City: Rogers

|

Posted: Feb 12, 2009 10:29 am Post subject: Posted: Feb 12, 2009 10:29 am Post subject: |

|

|

| JeffKnox wrote: | | grind away.... i grinded the shizzle out of both of mine |

Me too it seems that most people have to grind on em a little

_________________

Go Balls Deep Or Go Home |

|

| Back to top |

|

|

diegowhite

Faceplant

Joined: 23 Oct 2008

Posts: 36

City: Dublin

|

Posted: Feb 12, 2009 6:52 pm Post subject: Posted: Feb 12, 2009 6:52 pm Post subject: |

|

|

Thanks, guys, grinded that bitch down and she's totally flush now.

I put the TAV on the engine but the belt aint gripping at all, like as if the shaft aint long enough

Not having the manual doesn't help:(

|

| Description: |

|

| Filesize: |

148.1 KB |

| Viewed: |

9630 Time(s) |

|

| Description: |

|

| Filesize: |

149.73 KB |

| Viewed: |

9631 Time(s) |

|

| Description: |

|

| Filesize: |

167.76 KB |

| Viewed: |

9631 Time(s) |

|

| Description: |

|

| Filesize: |

143.82 KB |

| Viewed: |

9631 Time(s) |

Last edited by diegowhite on Feb 13, 2009 4:16 am; edited 1 time in total |

|

| Back to top |

|

|

JeffKnox

Backside 180

Joined: 09 Apr 2007

Posts: 2044

City: Jacksonville/Gainesville

|

Posted: Feb 12, 2009 8:44 pm Post subject: Posted: Feb 12, 2009 8:44 pm Post subject: |

|

|

video?

_________________

PAVT since '05/'06 |

|

| Back to top |

|

|

diegowhite

Faceplant

Joined: 23 Oct 2008

Posts: 36

City: Dublin

|

Posted: Feb 13, 2009 4:19 am Post subject: Posted: Feb 13, 2009 4:19 am Post subject: |

|

|

I don't have the engine running, was just moving it by hand.

I think I'm either going to have to float the TAV to get it in line or try to extend the shaft on the other side, any issues with floating it? the manual said not to

|

|

| Back to top |

|

|

paulmc

Frontside 180

Joined: 27 Nov 2007

Posts: 292

City: Manchester, UK

|

Posted: Feb 13, 2009 8:16 am Post subject: Posted: Feb 13, 2009 8:16 am Post subject: |

|

|

Looks like your shaft is poking out too far from the engine for the TAV.

With the TAV there is usually a metal collete that spaces the plate from the mounting, try without that collete as i looks like yours does not need the spacing. then put everything back as it was before.

http://www.hoffcocomet.com/comet/pdf/162608A-tav2-30-new.pdf

the spacer/collete i'm talking about is item 11 on the parts list. Also see instruction #4 in the manual.

by the way hope you find the instructions useful.

|

|

| Back to top |

|

|

ugly

Ollie

Joined: 23 Jun 2008

Posts: 57

|

Posted: Feb 13, 2009 10:31 am Post subject: Posted: Feb 13, 2009 10:31 am Post subject: |

|

|

I think you have the rear piece on this photo on backwards. I think it should have the flanged end facing the engine. Also, that bigger key lookin washer thing should fit inside one of those things...the belt doesnt rest on it. The belt will be slack until you power up the rev's and the TAV engages. I could be wrong though...i installed mine in like 2 mins and didnt really take note of how i did it.

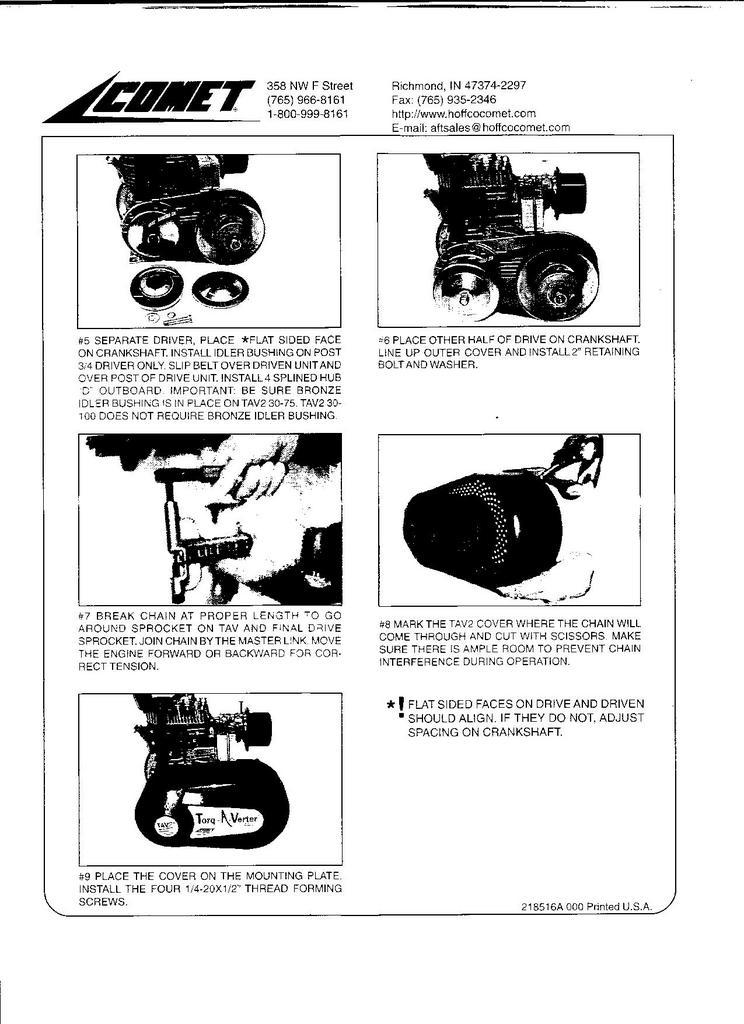

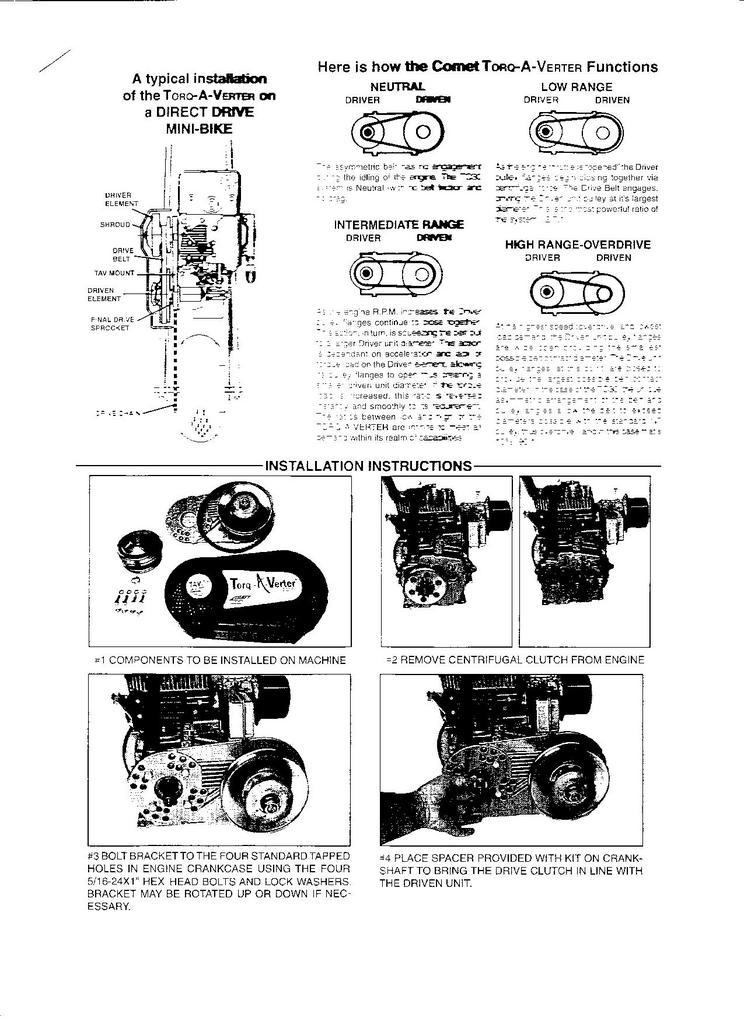

Here's the instructions if you can make anything out. I'm really not all that familiar so maybe this will help. The first page is on the bottom...then scroll up for the second page.

|

| Description: |

|

| Filesize: |

114.85 KB |

| Viewed: |

9587 Time(s) |

|

| Description: |

|

| Filesize: |

131.38 KB |

| Viewed: |

9587 Time(s) |

|

|

| Back to top |

|

|

diegowhite

Faceplant

Joined: 23 Oct 2008

Posts: 36

City: Dublin

|

Posted: Feb 13, 2009 10:47 am Post subject: Posted: Feb 13, 2009 10:47 am Post subject: |

|

|

| paulmc wrote: | Looks like your shaft is poking out too far from the engine for the TAV.

With the TAV there is usually a metal collete that spaces the plate from the mounting, try without that collete as i looks like yours does not need the spacing. then put everything back as it was before.

http://www.hoffcocomet.com/comet/pdf/162608A-tav2-30-new.pdf

the spacer/collete i'm talking about is item 11 on the parts list. Also see instruction #4 in the manual.

by the way hope you find the instructions useful. |

I've left out the collete all together in the above setup and it still comes 1/2" out too much (like it's a total 1" from the crankshaft)

Thanks for the instructions makes it easier  but i still dunno what to do to get the belt inline but i still dunno what to do to get the belt inline

|

|

| Back to top |

|

|

JeffKnox

Backside 180

Joined: 09 Apr 2007

Posts: 2044

City: Jacksonville/Gainesville

|

Posted: Feb 13, 2009 11:51 am Post subject: Posted: Feb 13, 2009 11:51 am Post subject: |

|

|

| diegowhite wrote: | | I don't have the engine running, was just moving it by hand. |

haha you do realize that the belt will stay slack until the engine reaches a certain rpm's right.... by moving it with your hand it should be slack because that is the purpose of a clutch lol.... while your engine is idling it should not engage

_________________

PAVT since '05/'06 |

|

| Back to top |

|

|

JB_CANSKATE

Backside 180

Joined: 06 Jul 2004

Posts: 1622

City: Markham, Ontario

|

Posted: Feb 13, 2009 12:35 pm Post subject: Posted: Feb 13, 2009 12:35 pm Post subject: |

|

|

I would try putting some washers in between the engine and the TAV mount until the belt is straight. See if that works.

I had to grind down the collete/spacer to make my tav fit on the briggs.

|

|

| Back to top |

|

|

diegowhite

Faceplant

Joined: 23 Oct 2008

Posts: 36

City: Dublin

|

Posted: Feb 16, 2009 3:19 pm Post subject: Posted: Feb 16, 2009 3:19 pm Post subject: |

|

|

| Right gonna order up the go kart axle tonight, whats the best way to mount the spool on it and with the chain running straight from the TAV what size sprocket should i have on the axle?

|

|

| Back to top |

|

|

paulmc

Frontside 180

Joined: 27 Nov 2007

Posts: 292

City: Manchester, UK

|

Posted: Feb 19, 2009 8:27 am Post subject: Posted: Feb 19, 2009 8:27 am Post subject: |

|

|

What does your spool look like? is it a releasing spool?

You want a sproket with about 60-70 teeth on it.

|

|

| Back to top |

|

|

diegowhite

Faceplant

Joined: 23 Oct 2008

Posts: 36

City: Dublin

|

Posted: Feb 19, 2009 9:03 am Post subject: Posted: Feb 19, 2009 9:03 am Post subject: |

|

|

| were building it ourself out of cutting discs and rods

|

|

| Back to top |

|

|

paulmc

Frontside 180

Joined: 27 Nov 2007

Posts: 292

City: Manchester, UK

|

Posted: Feb 19, 2009 12:00 pm Post subject: Posted: Feb 19, 2009 12:00 pm Post subject: |

|

|

| you want some axel hubs that will hold onto the cutting disc's aswell as hold onto the axel

|

|

| Back to top |

|

|

GnarShredd

Backside 180

Joined: 24 Jan 2009

Posts: 1529

City: Seattle

|

Posted: Feb 20, 2009 3:35 pm Post subject: Posted: Feb 20, 2009 3:35 pm Post subject: |

|

|

diegowhite, I keep hearing about a magic 1:6 ratio. (Example, 12 teeth on the TAV, 72 on the sprocket; or 10 on the TAV 60tooth sprocket). Then you can more finely adjust it with spool diameter.

this is pretty much just from my research and a friend who built one that works perfectly. I'm about 3/4 of the way done with mine. (Just need to figure out an engine mount and order an axel).

|

|

| Back to top |

|

|

diegowhite

Faceplant

Joined: 23 Oct 2008

Posts: 36

City: Dublin

|

Posted: Mar 02, 2009 9:02 am Post subject: Posted: Mar 02, 2009 9:02 am Post subject: |

|

|

| paulmc wrote: | | you want some axel hubs that will hold onto the cutting disc's aswell as hold onto the axel |

Is the hub then welded to the axle? any size hub do?

cheers

got two cutting disks for the spool ready to go

|

|

| Back to top |

|

|

paulmc

Frontside 180

Joined: 27 Nov 2007

Posts: 292

City: Manchester, UK

|

Posted: Mar 02, 2009 9:12 am Post subject: Posted: Mar 02, 2009 9:12 am Post subject: |

|

|

Usually they use grubb screws to hold onto the axel, hence an axle with a 1/4" key way is always a good idea.

like these kind of things....

http://www.bmikarts.com/shop/?shop=1&cat=172

|

|

| Back to top |

|

|

diegowhite

Faceplant

Joined: 23 Oct 2008

Posts: 36

City: Dublin

|

Posted: Mar 31, 2009 3:52 pm Post subject: Posted: Mar 31, 2009 3:52 pm Post subject: |

|

|

we got hubs but it has no grub screw holes only a keyway with keystock, do we drill holes into the hub. so bloody close to having it running and so many little things to get around

|

|

| Back to top |

|

|

ILwake12

Faceplant

Joined: 06 Mar 2008

Posts: 21

City: Milliken

|

Posted: Mar 31, 2009 5:10 pm Post subject: Posted: Mar 31, 2009 5:10 pm Post subject: |

|

|

| just a word of caution about the cutting disk spool idea, make sure you use some kind of wheel rim on the inside of the spool or the bolts will pull straight through the cutting disk (voice of experience, very frustrating)

|

|

| Back to top |

|

|

|

|

|